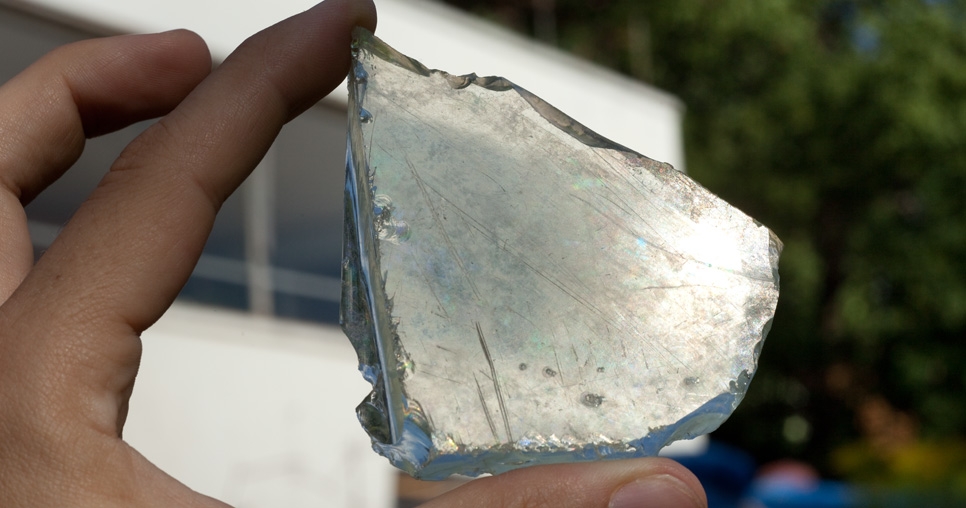

Glass fragment probably originating from the original glazing in the main living room (2nd floor), 2010, photograph: David Židlický

LIGHTENING THE ROOF STRUCTURES FOR SUBSEQUENT REMOVAL OF PERIPHERAL STRUCTURES OF THE GARDEN TERRACE

Before dismantling the travertine pavements and garden terrace steps it was necessary to remove the concrete flooring. In the space of the former ironing room (1st floor) a provisional supporting steel structure was installed, securing the roof plate of the terrace. The original garden terrace steel railing was dismantled and transported to a workshop for renovation and restoration.

EXTERNAL SEWERAGE AND GLASS FOUND

New stoneware horizontal sewerage was laid along the winter garden. Fragments of glass in various thickens (2.0 – 9.8 mm) were found during the excavation work. Samples of glass from this backfill were sent for detailed laboratory analyses to verify their authenticity. The glass of slightly yellowish shade with a thickness of 9.8 mm could originate from the original glazing of the main living space (2nd floor).

The so-called “TUNNEL” – air insulation hollow

In the space of the so-called tunnel (2nd floor), the coating of the steel ceiling beams was completed and the roof plate was renovated. One of the supporting reinforced concrete ribs was repaired by means of shotcrete with surface treatment adjusted to the period look.

RESTORATION AND CONSERVATION OF METAL ELEMENTS

Professional dismantling commenced, followed by transport of these elements that will not be treated “in situ“ to the artisan’s workshop:

steel consoles for central heating and sanitary installations distribution on the technical floor (1st floor)

garden terrace steel railing (2nd floor)

steel window casement of a continuous window in the drying room and ironing room (1st floor)

rolling blinds from the window boxes on the bedroom floor (3rd floor)

INTERNAL SEWERAGE

The camera inspection of the condition of the sewerage taking place in April defined sections where individual pieces or branches had to be removed and where the original pieces will undergo special repair. In those places where the replacement of horizontal and vertical sewerage cannot be replaced, the lining method was selected. The existing pieces were first cleaned by pressurised water. Then, the so-called textile sleeve was slipped into the original piece and resin was injected under pressure which, once hardened, created a new jacket inside the pipe with a long service life.

ROOF JACKET

The unauthentic worn out layers of the roof jacket (consisting of bitumen strips, screed with reinforcing steel, perlite-concrete and sand) were removed down to the original screed layer dated from 1930. This process demanding in terms of technology and time is still ongoing, approximately ¼ of the surface has been completed.

PREPARATION FOR STRUCTURAL SECURING OF THE GARDEN TERRACE

The design for the transfer of the exterior original plasters with the intention of their setting in the original position after the structural securing of the masonry is under way.

FURTHER WORK

Continuing grooving and installation of new wiring on the bedroom floor (3rd floor). During the second half of the month, the installation of heavy current lines was completed on the 2nd and 3rd floor.

Other pilot areas are tested in the main living space (2nd floor) for the restoration of interior plasters.

Unauthentic plasters were removed in the former laundry room (1st floor). When removing the secondary layers, a layer of authentic mortar was found with set in original tiles removed in the 1980’s.