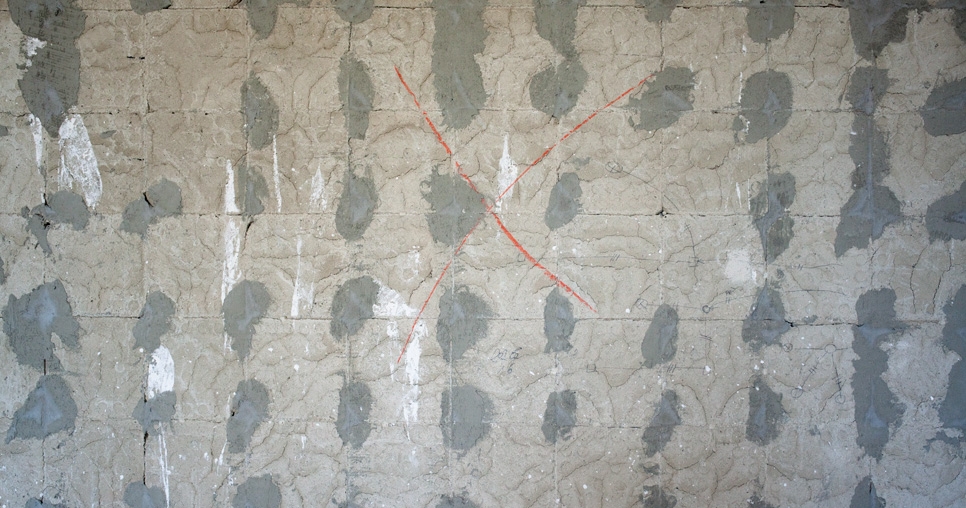

Main living room (2nd floor); structure of the steel glazed wall with the prime anticorrosive coat, 2011, photograph: David Židlický

METAL ELEMENTS

Continuing work on the reconstruction of the steel structures of the glazed wall in the main living room (2nd floor) and the renewal of the window sliding mechanism. Heating elements were embedded in concrete in the main living room. The restorers cleaned steel door frames on the technical floor (1st floor).

ROOF

The unauthentic concrete roof attic was lowered to the original level and the structure is ready for levelling. T-profile is being installed.

The existing metal sheet roofing and degraded wooden formwork were removed from the roof skylight over the bathroom in the parents‘ section (3rd floor), the restorers applied an antirust coating on the steel structure of the skylight.

FLOORS

Cracks in the original floor layers on the 3rd floor were repaired before applying the xylolite screed which covers the whole floor excerpt for the housekeeper‘s flat. In the main living room (2nd floor) , the xylolite screed covers approximately one third of the floor space size. In relation to this work, electric floor sockets were installed. The hollow in the floor of the children’s bathroom was filled with light-weight aggregate (expanded clay) and covered with concrete. Original distribution systems were preserved in the expanded clay backfill.

OTHER WORK

External insulation was installed on the upper terrace (foam glass fixed in hot asphalt) and dam proofing layer (asphalt modified strip of the first layer). Provisional roofing was removed from the space above the upper terrace.

Works continues on the renewal of the internal and external plasters. The internal plasters are jet grouted to reinforce their incoherent parts. Work continues in the laundry and kitchen on levelling the existing wall surface, which will be ready for ceramic tiles.

On the technical floor (1st floor) the thermal insulation is applied on the plumbing and central heating system (mineral insulation with smoothened plaster). Central heating distribution system installation continues on the 2nd and 3rd floors.

Concrete foundations and flue-gas ducting for the installation of historic boilers commenced in the boiler room (1st floor).

In the room under the garden terrace preparatory work continues on the peripheral masonry (floor filling up, damp proofing, strip foundation concreting).

The restorers clean the authentic black ceramic tiles discovered in the coke chute to reuse it.